Reactive Dye Printing Thickener Rg-Fa50176

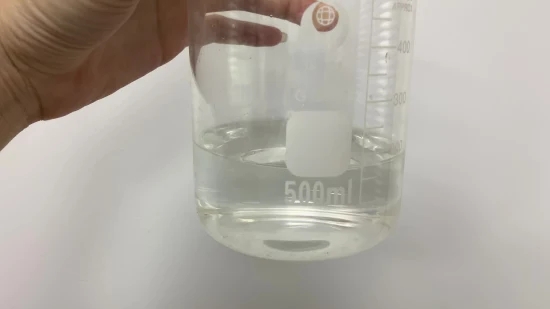

Reactive Printing ThickenerRG-FA50176 Chemical composition: Special acrylic ester natural pasteSpecification: Appearance

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | RG-FA50176 |

| Certification | REACH |

| Environmental Protection | Yes |

| Color | Brown |

| Kind | Synthetic Thickener |

| Appearance | Liquid |

| Application | Textile Printing Auxiliary, Dying Auxiliary |

| Ionicity | Anion |

| pH | 6.5~7.5 |

| Viscosity | 6000-15000MPa.S |

| Solid Content | >70% |

| Transport Package | Plastic Drum |

| Specification | 150KG |

| Trademark | RG |

| Origin | Weifang China |

| HS Code | 3906909000 |

| Production Capacity | 400mt/Month |

Product Description

Reactive Printing ThickenerRG-FA50176Chemical composition: Special acrylic ester natural pasteSpecification: Appearance: Pale yellow viscous liquidIonicity: AnionPH: 6.5~7.5Viscosity: 6000-15000mpa.sSolid content: >70%Application:Specialized in reactive dye printing on cotton and viscose/rayonProduct features:This product has strong cohesive force with water molecules, good in thickening effect, and hydration time short, easy to use, color field is high and brilliant. Has good stability and alkali resistance. It can be stored for a long time. It has better permeability, clear lines and brilliant color in the rotary screen printing and flat screen printing. Taking off the paste fast after washing, handle feeling is good, especially for hard handle feeling, such as navy blue, coffee and black etc, soft effect is obvious and has excellent stability about storage.This product is APEO-free.Application reference recipe I: firstly prepare stock paste, then make printing paste.1.

| Stock paste preparation: | ||

| Thickener RG-FA50176 | 7-9g | Stir till expansion absolutely |

| Sodium Hexametaphosphate: | 0-1g | |

| Resist Salt S: | 2-3g | |

| Add water to total amount: | 100g | |

| Printing Paste Preparation: | ||

| Stock paste: | 40-70 g | Stirring evenly |

| Reactive dyes: | X g | |

| Sodium Bicarbonate: | 2 g | |

| Sodium Carbonate: | 1 g | |

| Urea: | 5-15 g | |

| Add water to total amount: | 100 g | |

Application reference recipe II:Prepare printing paste directly.

| Printing Paste Preparation: | ||

| Reactive dyes: | X g | Stirring evenly with High speed |

| Sodium Bicarbonate: | 2 g | |

| Sodium Carbonate: | 1 g | |

| Urea: | 5-15 g | |

| Resist Salt S: | 1.5 g | |

| Sodium Polyphosphate: | 0-2 g | |

| Thickener RG-FA50176: | 3-4 g | |

| Add water to total amount: | 100 g | |

Related Products

-

![10 Years Experience in Plant Extract The Best Service and The Best Price to Develop Overseas Markets. Welcome New Friends Win-Win Cooperation. Cordyceps]()

10 Years Experience in Plant Extract The Best Service and The Best Price to Develop Overseas Markets. Welcome New Friends Win-Win Cooperation. Cordyceps

-

![Wholesale Original Brand Elfworld Mc 8500 Puffs Disposable Vape Pen Electronic Cigarette Vapes Hot Selling in UK USA Best Taste and Nice Aromas]()

Wholesale Original Brand Elfworld Mc 8500 Puffs Disposable Vape Pen Electronic Cigarette Vapes Hot Selling in UK USA Best Taste and Nice Aromas

-

![Cheap Price Synthetic Beta Carotene Powder as Food Colorant]()

Cheap Price Synthetic Beta Carotene Powder as Food Colorant

-

![Pharmaceutical Intermediate API CAS 59870-68-7 Glabridin]()

Pharmaceutical Intermediate API CAS 59870-68-7 Glabridin